Description

Easy to clean, mastic free/high integrity vacuum connections, optional glass viewport

- Rugged steel outer body

- Quarter turn twist-lock handles

- Blanking plugs for unused connections

- Glass viewport in machined aluminium resin trap lid

- Clear, disposable PVC shield for underside of lid

- Silicone rubber guide tube to reduce resin spatter

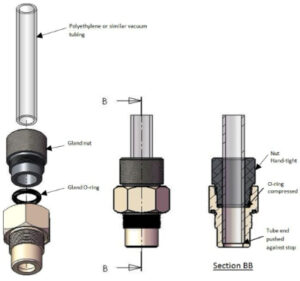

- Very effective O-ring tubing glands. These seal on the OUTSIDE of tube – out of the resin path

- End of tube completely unobstructed. Allows free resin exit

- 12 litre (3.1 gal), heat resistant, disposable catchpot (or optional degas bucket)

- Tortuous air exit from catchpot. This contains resin spatter and keeps trap body clean

- Rugged solid block manifold rigidly locked to trap body. Cannot loosen and leak

- Vacuum regulation valve with silencer (optional)

- O-ring mounted vacuum gauge, can be rotated to face any direction

- Vacuum pump connection on side of trap body, not on trap lid. Pump connection not disturbed when trap lid removed.

Hassle free by design

The RT19 resin trap and degassing vessel is primarily designed to collect excess resin from composite manufacturing processes, reducing the risk of resin entry to vacuum pumps and central vacuum lines. Built to last, the RT19 features mastic-free high integrity vacuum connections mounted in a heavy duty machined aluminium trap lid fitted with a 75 mm (3″) diameter glass viewport, a rugged vacuum pump connection block and a disposable resin catchpot. With slightly modified vacuum connections, the RT19 may also be used for supplying degassed resin to parts being infused.

Dispose of the catchpot – not the resin trap

With the RT19 you buy the resin trap once, and then simply use a disposable 12 litre (3.1 US gallon) heat resistant catchpot or an 11 litre (2.9 US gallon) polyethylene resin degassing bucket as required. The RT19 is specifically designed to ensure all resin spatter is carefully contained within the disposable catchpot. This keeps the resin trap body clean and tidy, even with continuous use. The RT19 really is the low risk, low maintenance option for serious composites manufacturing professionals.

Remarkably effective resin trap lid connections:

-

-

-

-

-

-

-

-

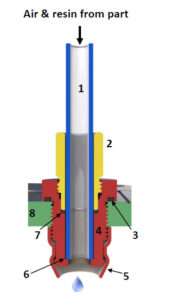

- Extruded translucent vacuum tubing (usually polyethylene)

- Machined aluminium gland nut. Approximately ¼ turn to loosen and ¼ turn to tighten. Does not need to be completely undone for tube entry or removal. Supports tube to maintain tube shape at the O-ring seal (7).

- Viton gland body to trap lid O-ring seal

- Machined steel gland body

- Silicone rubber anti-spatter tube. Directs resin down into the disposable catchpot for no mess cleaning

- Vacuum tube terminates at an external stop below resin trap lid. Note how the tube exit is completely open for unobstructed resin exit

- Tubing gland O-ring seal. Seals on outside of tube, well above the tube exit. Provides a quick and reliable mastic-free seal.

- Trap lid

As one delighted Vacmobile user remarked…

“The system of putting tubes in the resin trap works fantastic. You don’t need to drill them out and the resin falls directly into the catchpot. We should have bought this equipment one year ago!”

-

-

-

-

-

-

-

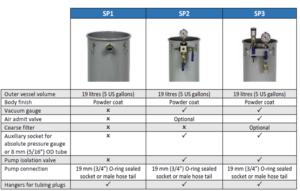

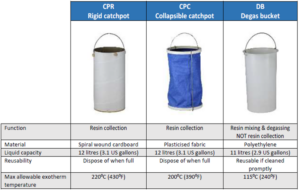

Resin Trap Options

RT19 vessels are assembled from a range of modular components and may be configured to suit specific needs.

Option examples are illustrated in the tables following.

Body side port configurations

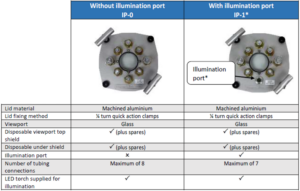

Trap lid options

Connection gland options

When used with vacuum tubing such as extruded polyethylene, Vacmobile O-ring sealed tubing connection glands deliver high integrity vacuum seals with remarkable ease. No mastic is required and resin exiting from the tube drops directly into the catchpot without any obstruction to flow.

The connections are available to suit the following tubing OUTSIDE DIAMETERS (OD):

- 9.5 to 10 mm – 3/8” nominal OD

- 12 to 12.5 mm

- 12.5 to 13 mm – 1/2” nominal OD

- 15.5 to 16 mm – 5/8” nominal OD

- 18.6 to 19.1 mm – 3/4” nominal OD

Adaptors are available to suit 1/2” and 3/4” inside diameter tube.

Base and castor options

Internal catchpot/degas bucket options

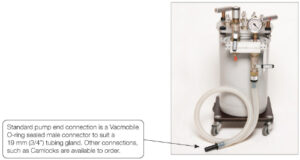

Optional silicone rubber hose kit

The standard connection hose kit is a 1.2 metre (47”) length of wire reinforced tubing with male terminations to suit 19 mm (3/4”) Vacmobile tubing glands.

Unusually for a vacuum hose of this diameter, the wire reinforced silicone rubber vacuum hose is extremely flexible, which simplifies hose fitting and trap positioning. The hose may be used at temperatures up to 200°C (400°F).

The standard hose kit may be extended in multiples of 1.2 metres (47”) via standard joiners for 19 mm (3/4”) ID tube. Under vacuum, the tube will seal tightly to fittings and hose clips are not required.

Optional resin degassing accessory – degasses resin on the way in to the vessel

Of interest to users wanting to degas resin prior to infusion, or for resin casting applications, we have found that degassing a thin stream of resin on the way in to a pre-evacuated vessel has the following benefits over degassing bulk resin:

- Greater air removal because the thin resin stream exposes a much larger surface area to vacuum

- Froth formation is minimized, as the large bubbles break as they enter the vessel. This allows much more resin to be collected in the degas bucket without risk of overflowing – up to 9 litres (2.4 US gallons) per batch

- The method is effective with high viscosity resins which are very difficult or impossible to degas in bulk.

The Degas-on-the-way-in accessory is quickly fitted to the RT19’s lid.

Degas Kit

Degas Kit

Reviews

There are no reviews yet.