Description

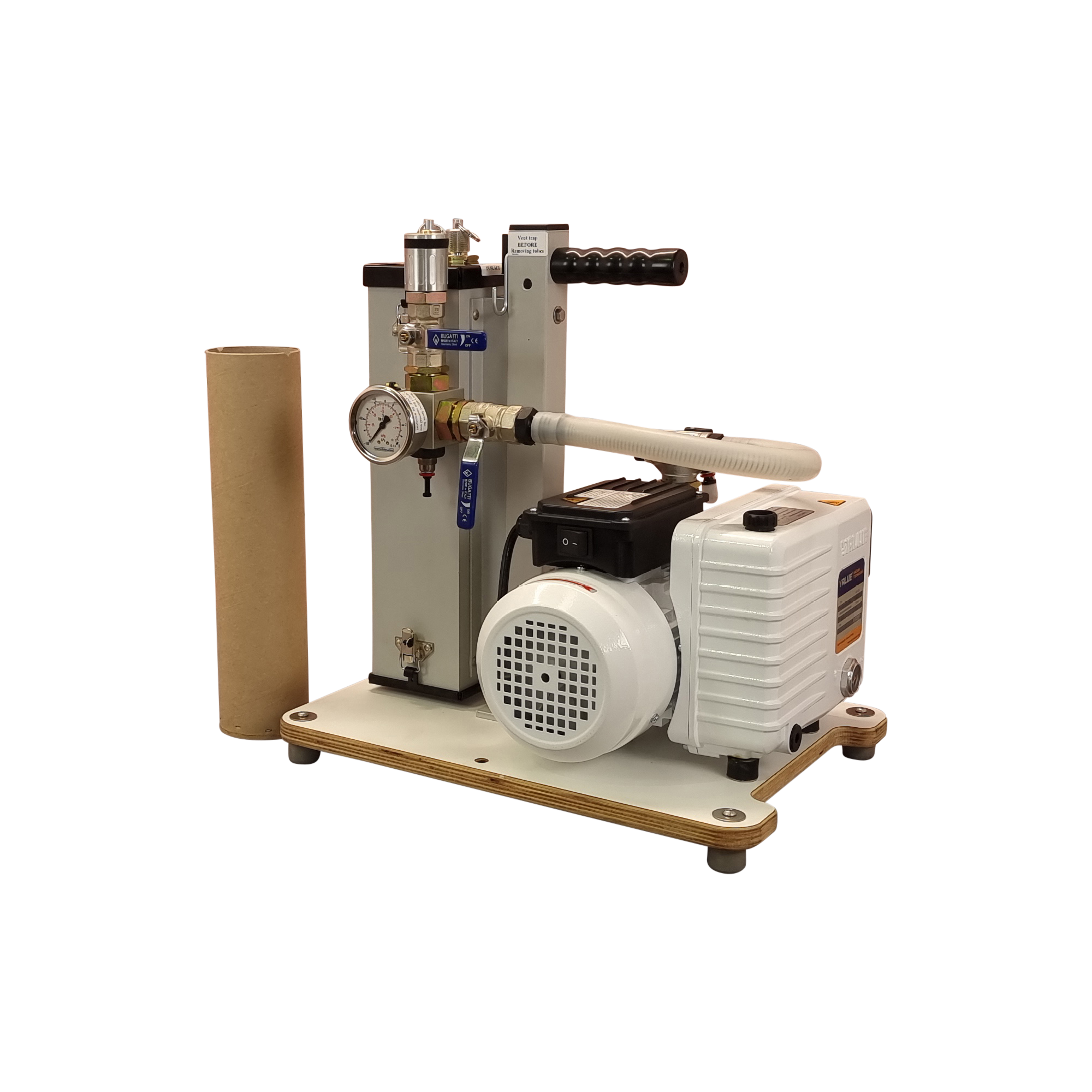

Ready to infuse, right out of the box, the Vacmobile E2- series is a compacted down form of our original 20/2 machine, using the same resin trap body and 2 litre (4 pint) disposable resin catchpot. The primary uses of the E2- are the manufacture of laminates using resin infusion or vacuum bagging over wet laminate or pre-preg. As supplied from the factory, E2- machines are not mobile, but they are easily added to a customer supplied mobile cart if bench top mounting is not appropriate.

For 230 volt, markets, the E2- may be fitted with 8 m3/h, or 20 m3/h nominal capacity vacuum pumps. For 115 volt/60 Hz markets the only pump option is the VSV-20 pump with a capacity of 14.1 cfm (24 m3/h). The high vacuum VSV-20 vacuum pump is fitted with an End Vacuum Adjustment Valve (EVA valve) as standard. This precisely adjustable valve significantly improves the versatility of the system. Please refer to the Modular 2S data sheet for more information about the EVA valve.

The maximum laminate size that can be infused by an E2 series machine very much depends on the experience of the laminator, especially familiarity with the use of wide peel ply resin breaks around the perimeter of the laminate.

For more detail on this system, please open the PDF.

Trap Lid Options

Glass lid for infusion Steel Lid for vacuum bagging

Reviews

There are no reviews yet.