The benefits of using a Vacmobile for resin infusion and other vacuum bagging processes

“We should have bought this equipment one year ago!” [Customer – Belgium]

Vacmobiles simplify and improve vacuum bagging processes such as resin infusion. Here’s how…

For infusion type processes the critical factors in regard to vacuum are:![]()

1. Avoiding air leakage into the laminate

2. Being able to easily verify that there is no air leakage into the mold or bag prior to infusion

3. Achieving maximum air and vapor removal from the part prior to infusion

4. Avoiding porosity caused by water and solvent vapors

5. Maintaining a controlled level of vacuum until the resin has gained acceptable strength

6. Achieving the foregoing in a productive and cost effective manner.

The first factor is a function of the choice of materials, molding system and laminator skill. Through attending to details such the long term leak tightness of joints, ease of control and system size reduction and mobility (allowing Vacmobiles to be placed physically close to parts), using Vacmobiles optimizes the remaining factors. The benefits delivered by Vacmobiles are:

- Better vacuum in the laminate (because the potential for vacuum leaks is much reduced and tube lengths are shorter)

- Faster and more reliable leak testing (drop testing)

- Simple control process right at the point of use

- Zero risk of work in another part of the plant causing a loss of vacuum (because Vacmobiles are intended to be applied to one part at a time and not shared across multiple parts)

- Less capital cost than a permanently piped system of equivalent performance

- Less energy usage than a permanently piped system of equivalent performance

- Much more flexibility of use. Very easily relocated at negligible cost if needs change.

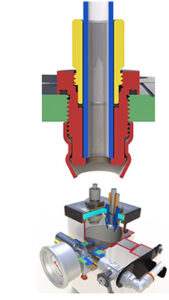

Please see diagram below for a more detailed explanation of the key benefits of using Vacmobiles.

Examples of design details that improve vacuum bagging processes:

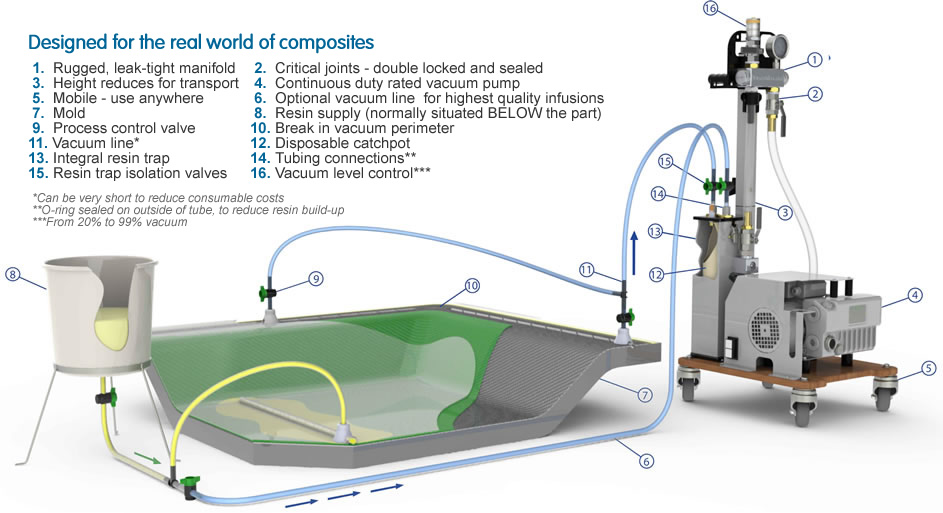

Vacmobile resin traps require much less cleaning

Resin entering a resin trap under vacuum tends to spatter and foam up. Most resin traps do not deal with these problems and become messy and extremely difficult to clean after little use. In contrast, Vacmobile resin traps can remain in service for years with negligible attention.

This is achieved by catching the resin in a close fitting, heat resistant, disposable, internal catchpot and by guiding the air flow path through the resin trap so that spatter is directed on to disposable surfaces.

Dispose of the catchpot – not the resin trap

With a Vacmobile you buy the resin trap once, and then simply use a disposable heat resistant cardboard catchpot or polyethylene resin degassing bucket as required.

Vacmobile Resin Traps are specifically designed to ensure all resin spatter is carefully contained within the disposable catchpot. This keeps the resin trap body clean and tidy, even with continuous use.

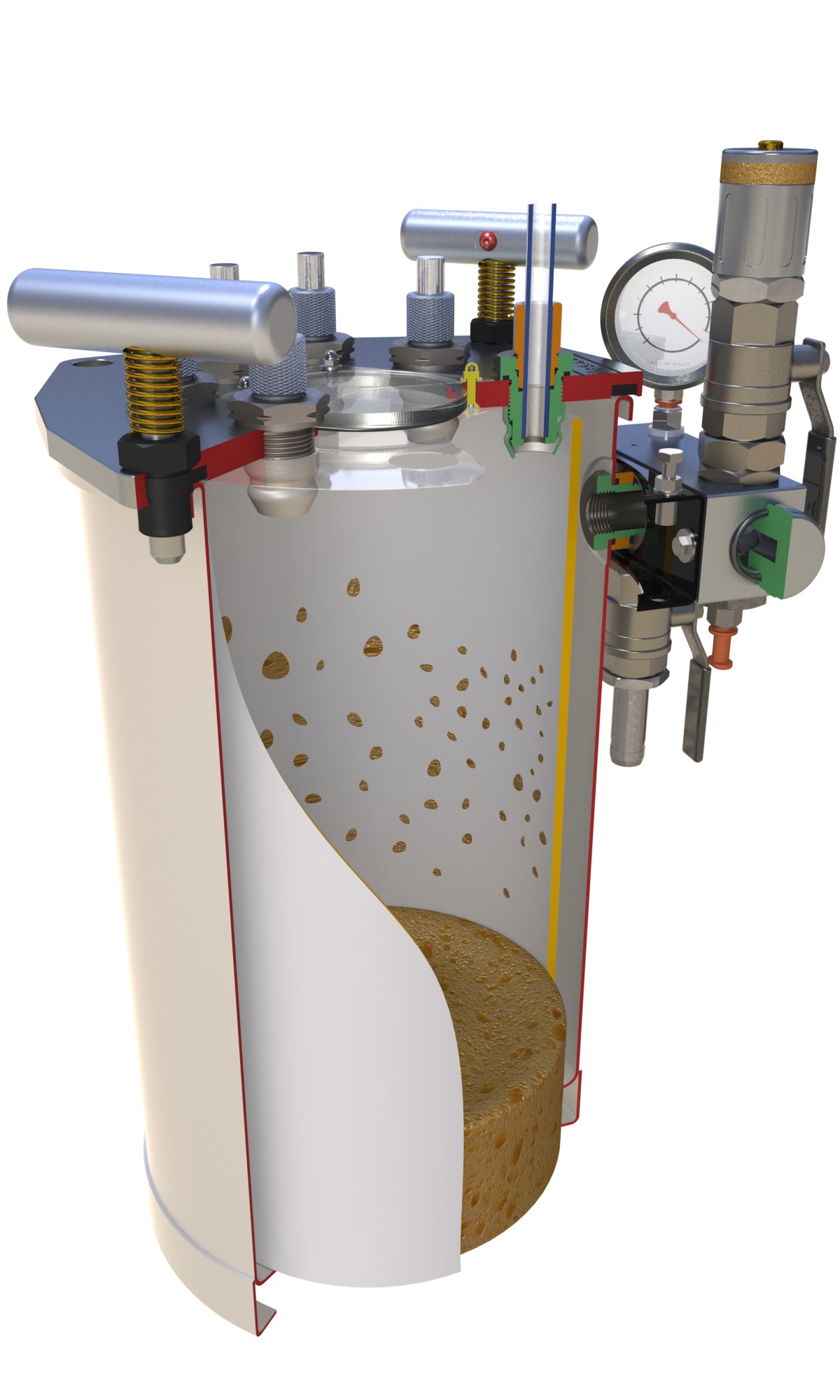

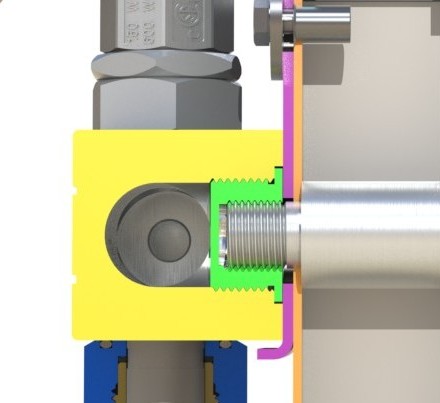

Vacmobile O-ring sealed vacuum tubing connections (gland fittings) do not restrict resin flow into the resin trap

Most other resin trap connections require the vacuum tube from the laminate to be fitted over a male hose tail. As a result, resin entering the trap builds up on/inside the hose tail, blocking the hose tail when the resin gels.

In contrast, Vacmobile connection glands are O-ring sealed on the outside of the tube. Furthermore, the completely open end of the

vacuum tube terminates below the underside of the lid of the resin trap.

Resin exiting from the vacuum tube drips without restriction directly into the waiting catchpot.

Remarkably effective resin trap lid connections

As one delighted Vacmobile user remarked …

“The system of putting tubes in the resin trap works fantastic. You don’t need to drill them out and the resin falls directly into the catchpot. We should have bought this equipment one year ago!”

- Extruded translucent vacuum tubing (usually polyethylene)

- Machined aluminium gland nut. Approximately ¼ turn to loosen and ¼ turn to tighten. Does not need to be completely undone for tube entry or removal. Supports tube to maintain tube shape at the O-ring seal (7).

- Viton gland body to trap lid O-ring seal

- Machined steel gland body

- Silicone rubber anti-spatter tube. Directs resin down into the disposable catchpot for no mess cleaning

- Vacuum tube terminates at an external stop below resin trap lid. Note how the tube exit is completely open for unobstructed resin exit

- Tubing gland O-ring seal. Seals on outside of tube, well above the tube exit. Provides a quick and reliable mastic-free seal.

- Trap lid

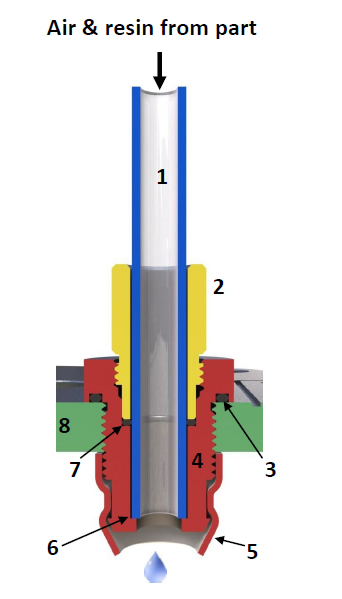

Critical joints in Vacmobiles cannot be loosened – and therefore cannot leak – in normal service

When making high quality composites using vacuum processes, it is usually necessary to perform a leak test (drop test) to confirm that air is not leaking into the laminate.

If the vacuum system itself is a source of leaks a drop test will be meaningless.

The leak-prone points in most vacuum systems are the joints between parts of the system, e.g., valves to manifolds. These loosen over time and develop vacuum leaks, which can be difficult to find and repair.

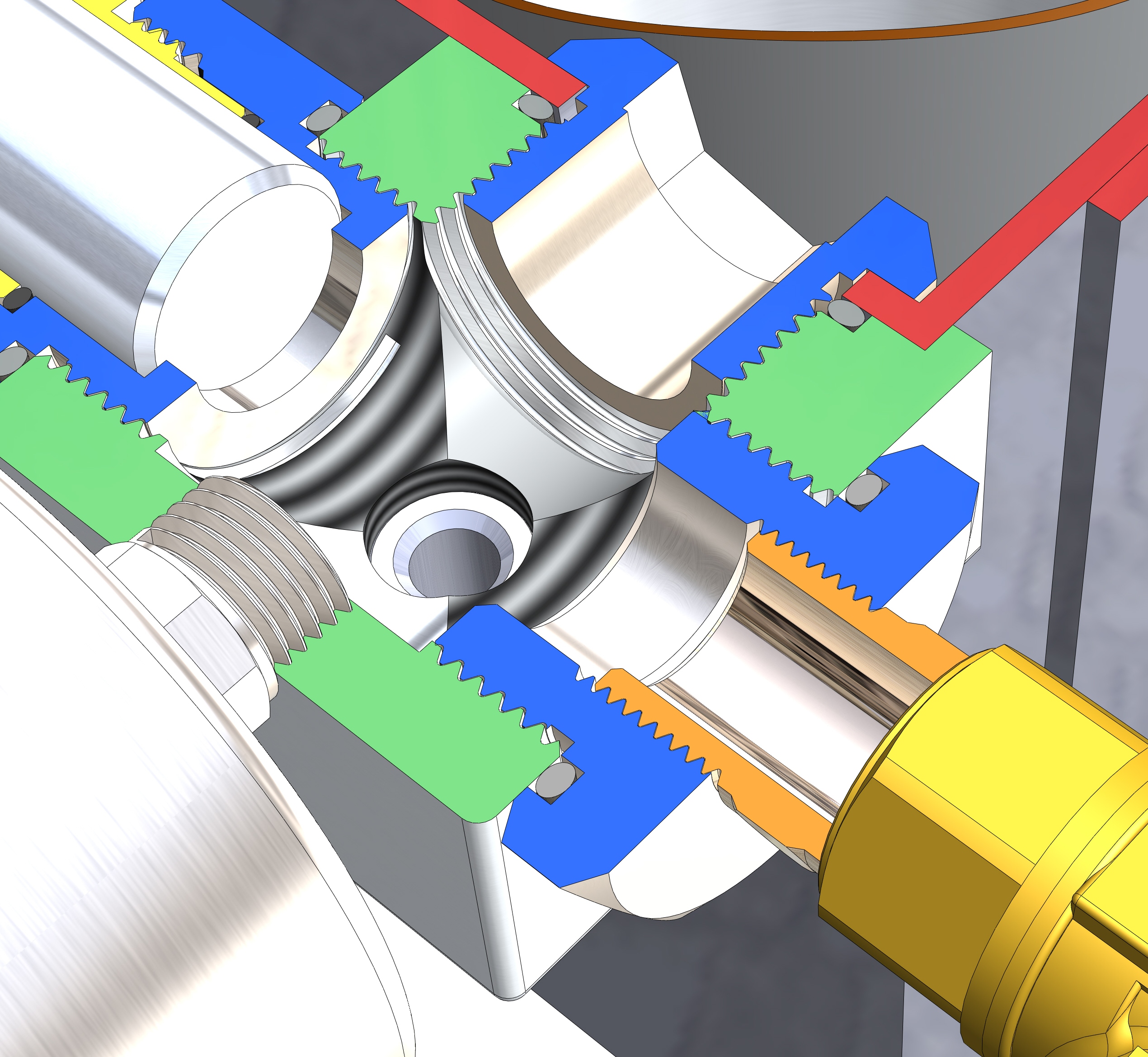

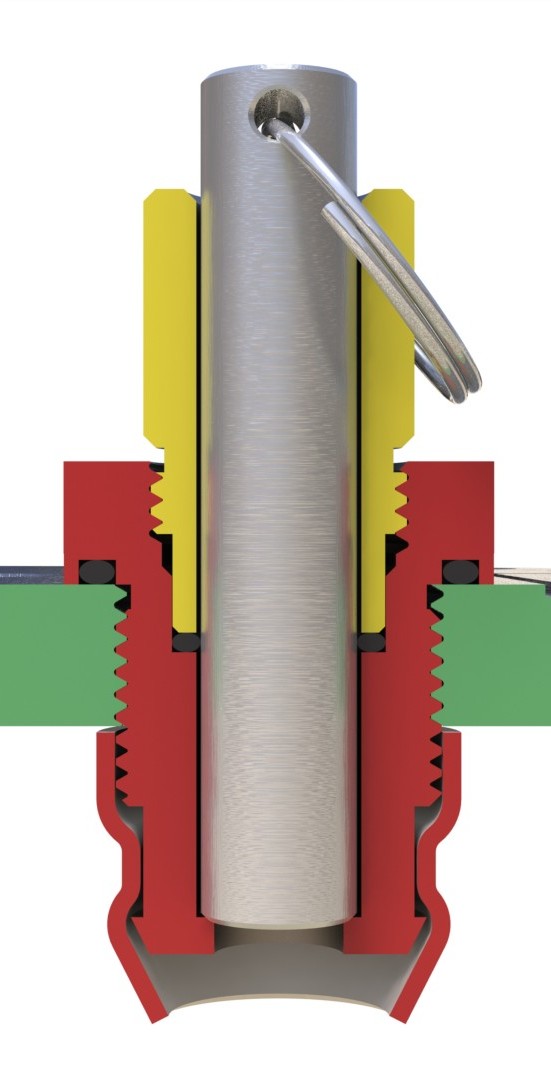

All permanent joints are mechanically locked

With Vacmobiles, all permanent joints in the machine potentially subject to stress in operation, e.g., valves being open or closed, or parts of the machine which might receive impact, are mechanically locked in some manner.

Even in very severe duty use, permanent joints in Vacmobile machines will not loosen and will not develop leaks.

Manifold mechanically locked to main handle upright (Vacmobile 20/2 machine)

Manifold mechanically locked to resin trap body (Vacmobile MICRO 8/2 machine)

Vacmobiles can easily be checked for leak-tightness by the laminator

As noted above, a critical preliminary step in the resin infusion process is a drop test to confirm that there is no air leakage into the laminate.

is a drop test to confirm that there is no air leakage into the laminate.

The simple way to perform a drop test is to check the reading of a vacuum gauge or an absolute pressure gauge connected to the resin trap. However, observing the vacuum leakage rate at the resin trap is only meaningful if the resin trap itself is known to be leak tight. With a Vacmobile, checking the vacuum tightness of the resin trap is simple. All you do is temporarily fit blanking plugs into the O-ring sealed tubing glands on the resin trap lid, evacuate the trap, close the valve to the vacuum pump and watch the gauge.

Once the trap has been checked in this way, you can remove the test plugs and fit the vacuum tubing from the part, knowing that the O-ring seal inside a Vacmobile connection gland will seal reliably to the extruded vacuum tubing typically used for resin infusion. If the resin trap has been pre-tested with blanking plugs in the tubing connections, the subsequent drop test will accurately indicate the leak tightness of the part and the tubing from the part to the resin trap.

Integration of the vacuum pump, the resin trap and the vacuum controls, plus good design allows for compactness

Combining compactness with single phase power and mobility means that the complete vacuum system can generally be placed alongside the work. This delivers a number of benefits:

- It automatically avoids long vacuum lines, which are inherently prone to damage and vacuum leakage. Threaded metal vacuum lines generally develop leaks at the joints over time. Plastic vacuum lines typically crack as they age. Flexible vacuum hoses are inevitably damage prone if they can be walked on.

- Long vacuum lines typically have several access points in them. These are prone to leakage but, even worse, they are likely to be used by others just at the wrong time. I.e., when Jack is a critical stage of his process, Jill decides to start her job and Jack risks losing his part.

- Long vacuum lines through a factory typically require larger 3 phase pumps and the whole system is likely to be much more expensive to install and more expensive to run than a few dedicated Vacmobiles.

- Process control is much enhanced if each laminator has total control over his own vacuum supply, which will never be the case with a shared system

- Placing the vacuum system close to the job leads to better vacuum in the part, which leads to better quality composites.

The end results of being able to put the vacuum system right next to the work are:

- Reduced capital cost compared with fixed vacuum systems

- Better laminate quality

- Improved productivity

- Greater flexibility of use and more future proof if needs change.

Equipping a laminator with a Vacmobile is similar to a builder replacing a mains powered drill with a good cordless drill. For a builder, the utility of the mains powered drill just does not compare with the utility of a good cordless drill.