We introduce this note with a word of caution!

While the following describes a method for transferring a batch of resin from anevacuated vessel into a laminate to be infused without air entry, we are not sure that the end result will be a completely void-free part. This is because applying a vacuum above a static volume of liquid resin does not necessarily remove all the dissolved air. Vacuum degassing may need to be assisted by materials which encourage bubble formation, such as Scotch-Brite, or by the application of heat, or by agitation or by centrifuging. Suggestions for removing voids from infused parts will be most welcome! We will update this note as we learn more…

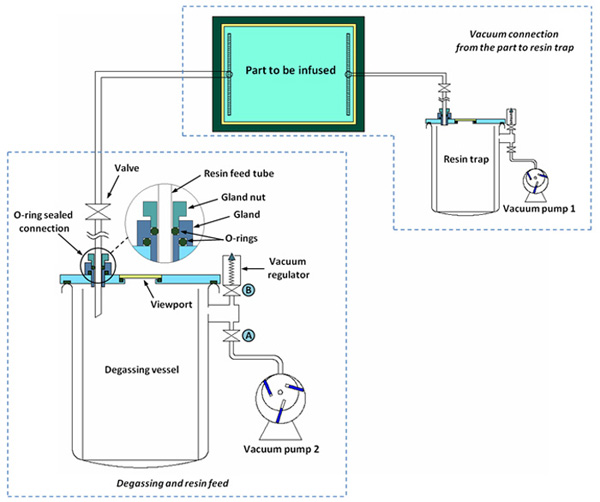

Subject to the limitation above, it is possible to vacuum degas resin and feed it into a part to be infused without further air contact after degassing. If carefully sequenced, the procedure can be accomplished with one vacuum system, but it is simpler and there is less risk of a mistake if two vacuum systems are used. We will describe the procedure on the assumption that the following equipment is available:

- One vacuum system with an appropriate resin trap for applying vacuum to the part to be infused.

- Another vacuum system with a suitable vessel for degassing resin. This degassing vessel needs at least one O-ring sealed vacuum connection which a resin feed tube can be pushed through (and remain sealed during movement).

- Desirably a disposable O-ring sealed valve that can be inserted into the resin feed line. (A tube clamp will work, but a valve will be easier to use).

With reference to the schematic below, the vacuum connection(s) from the resin trap can be connected to the part in the normal way. The degassing and resin feed line(s) should be set up as in the lower section of the drawing.

Procedure for feeding degassed resin

Refer to the following drawings and proceed as outlined below.

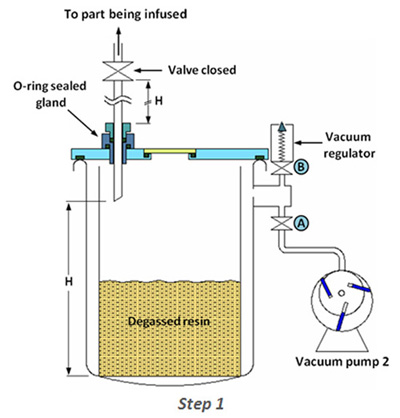

- Make up a resin feed tube from the part to the degassing vessel, so the tube can be inserted through the lid of the degassing vessel as shown in Step 1. Note that the bottom end of the tube should be cut an angle to avoid it sealing off on the bottom of the resin bucket in Step 2. The valve must be positioned at least distance “H” above the top of the gland in the degassing vessel lid.

- Close the valve in the resin feed tube. Prepare the part to be infused in the normal way, by first evacuating and leak testing the part via the resin trap and vacuum pump 1. (See main schematic.) After leak testing, restore vacuum to the part using the resin trap and vacuum pump 1.

- At least 30 minutes before degassing, start vacuum pump 2 and close valve A. This early start is to ensure the pump is warm before degassing begins, as a warm pump is better able to handle water vapour and other volatile components which may evolve from the resin during degassing.

- When satisfied that the part is ready for infusion, mix the resin and place the resin bucket in the degassing vessel. (Leaving plenty of room for expansion during degassing – as much as 2x to 4x the initial liquid resin volume. Ideally check the volume expansion with a test on a small amount first.)

- Insert the angle cut end of the resin feed tube through the loosened gland. As shown in Step 1, the angle cut end of the tube should terminate just below the lid of the degassing vessel. Once in the Step 1 position, the nut on the O-ring gland should be tightened sufficiently to temporarily retain the tube in this position.

- Fit the lid on the degassing vessel, noting that the angle cut end of the tube must be well above the resin at this stage. This is important, as it allows the air to be removed from below the resin feed valve.

- If the resin is to be degassed at maximum vacuum, make sure valve B (below the vacuum regulator) is closed. Note that degassing at maximum vacuum may not be advisable with resin systems which have a high vapour pressure (such as polyester resins containing MEKP). For high vapour pressure resins, preset the vacuum regulator so the degassing pressure is above the vapour pressure of the mixed resin at your ambient temperature. (With pressures measured in absolute pressure terms.)

- Open valve A to the vacuum pump 2.

- Degas the resin and observe progress through the viewport in the degassing vessel’s lid.

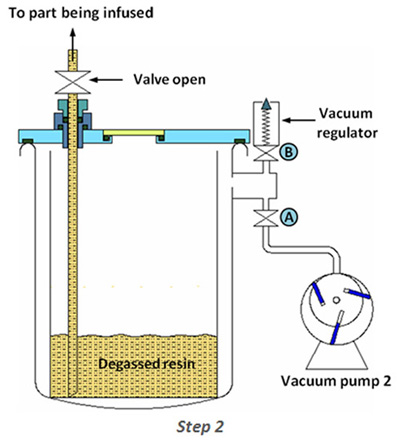

- When the resin has been degassed, slightly loosen the gland nut retaining the resin feed tube. Push the tube until the angle-cut end contacts the bottom of the resin bucket – as shown in Step 2. Retighten the gland nut.

- Open the resin feed valve above the degassing vessel.

- Open valve “B” under the vacuum regulator and adjust the vacuum level so the air pressure rises (vacuum decreases) above the resin in the degassing vessel. Adjust the vacuum until the flow rate of resin appears satisfactory. If need be, close valve” A” above vacuum pump 2 and admit atmospheric pressure air above the resin (but leave the vacuum pump running).

- After the part has been completely infused:

a) For low vapour pressure resins which are not affected by maximum vacuum, close valve “B” under the vacuum regulator and reopen valve “A” to vacuum pump 2 (if previously closed), or

b) For high vapour pressure resins (see note 7 above), open valve “B” below the vacuum regulator and hold the vacuum at the safe level for the resin until it has cured. - Excess resin will now return from the resin feed side of the part. As long as the resin viscosity is still low enough, reapplying vacuum to the resin feed side of the part will apply more consistent vacuum to the whole part. This will eliminate the resin rich area typically found at the resin feed side of the part.

Sorry if this appears complicated! With a little practice, this procedure will be found to be quite straightforward.

Feedback or queries on this note?

We are keen to improve the accuracy and value of Vacman’s Notes. If you have any feedback or queries regarding this note, or would like to suggest new topics to be covered, Vacman would be pleased to hear from you! Please comment below! Or email [email protected]